ORBIT EQUIPMENTS P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to ORBIT EQUIPMENTS P.LTD.

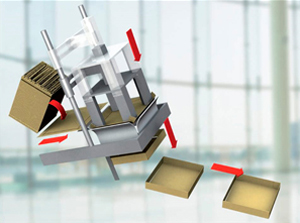

Case Packers

Lube Oil Case Packer

Case Packer for Lubeoil Containers

Lube Oil Case Packer

Case Packers For HDPE Containers

Case Packer For Soaps

Drop Packer For Bottles

Soaps Case Packer

CASE PACKER – BOTTOM LOADING

The Bottom Load Case Packer design provides maximum access to all of the drive components from one side of the machine while maintaining a compact footprint. The Bottom Load Case Packer is ideally suited for pharmaceutical, personal care and medical device applications with stainless steel construction that meets all sanitary and FDA validation requirements.

After the case is picked and erected, collated product is gently elevated upward into the case. Our product load funnel ensures accurate loading of product into the case. Minor and major flaps are then folded with precision as the case moves through the take-away section. The case is sealed with either BOPP tape or glued and then smoothly discharged.

CASE PCKER – TOP LOADING / PICK & PLACE

The Pick and Place Case Packer does the automatic packaging of rigid containers the most varied formats, like bottles, jars, cans, trays, carton shells and packages, sachets and pillow bags.

The product’s handling is done through the Pick and Place arm, equipped with suction cups or grippers, according to the package shape. Its arm does a lateral movement for case packing, with a small foot-print, which saves room at the production line.

Pick and Place Case Packer receives pre-erected cases and products from the filling line, splits the products on rows according to the packing pattern and softly places products in the pre erected cases.

CASE PACKER – SIDE LOADING

Side load case packers are designed to load products into an open case on its side.

Working with an in-feed system, the products are collated in the correct pack configuration and then loaded horizontally into the open case lying on its side.

Side load case packers are available in many frame sizes and we offer a range of in-feed systems for handling a variety of primary products such as cartons, pouches or trays.

With a compact footprint, side load case packers provide operators with floor level access inside the machine.

Size changes can be manually completed in less than 10 minutes without the need to change parts.

DROP CASE PACKER

The Drop Packer is a fully automatic machine that accepts erected corrugated trays / cartons, and loads them with containers, controlling both handle and label orientation. It delivers the fully loaded tray / carton to an output conveyor. The machine performs its function in response to the presence of product on the in feed conveyor and the supply of trays / cartons in the loading station.

The Drop Packer is a continuously operating packaging machine. Whether it is boxes, bottles, jars, cans, or cartons, it can pack virtually all conceivable products, thereby enabling outputs of up to 60 trays/cases per minute. The format-flexibility of the tray line provides the ability of producing open trays, trays with shoulder tabs, and shoulder trays. The modular design enables the use of the Tray Packer in the most versatile fields of operation. Excellent vision at each working station, optimum operator access and the extremely simple control unit is user friendly.

WRAP AROUND CASE PACKER

The intermittent Wraparound Case Packers caters for speeds of up to 15 cases per minute. All Machines in the range feature Servo Drive Technology offering the customer State of the Art Performance.

The wraparound case packer is an intermittent motion machine able to pack bottles, jars, cans or packets into wraparound style cases. This machine features an individually designed product in feed system to meet customer specific requirements.

The unique dual servo driven case transfer system enables case length selection to be done via the operator interface screen, eliminating difficult mechanical size change adjustments. The HMI rotates about the centre line of the machine to provide operator control from either side of the machine.

This machine can be supplied to handle either Internal or External Glue Lap.

Full size guard doors on both sides of the machine offer complete access for operator intervention. Fully Automatic adjusting product paddles guarantee higher reliability and precision when changing to a new carton size.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.